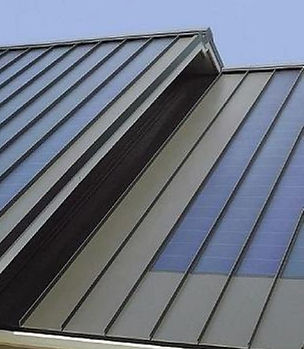

Premium architectural metal roofing with concealed fixings, delivering sleek aesthetics and superior weathertightness.

Standing seam roofing is a premium metal roofing system characterized by vertical metal panels with raised seams that interlock. The concealed fixing system creates a clean, modern appearance with no exposed fasteners, while providing exceptional weather protection and longevity.

Economical system where adjacent panels snap together without specialist tools. Suitable for pitches down to 3 degrees.

Premium system with double-lock seaming using specialist machinery. Provides the ultimate in weathertightness.

Traditional rolled seam system ideal for complex roof shapes and heritage applications.

Specialist systems for curved roofs, barrel vaults, and architectural features.

Standing seam roofing is available in various metals:

Standing seam roofing is ideal for:

Standing seam roofing requires specialist knowledge and equipment. Our experienced teams have extensive training in the installation of all standing seam systems, ensuring your roof delivers outstanding performance and appearance for decades to come.

Get in touch to discuss how standing seam roofing can enhance your project.